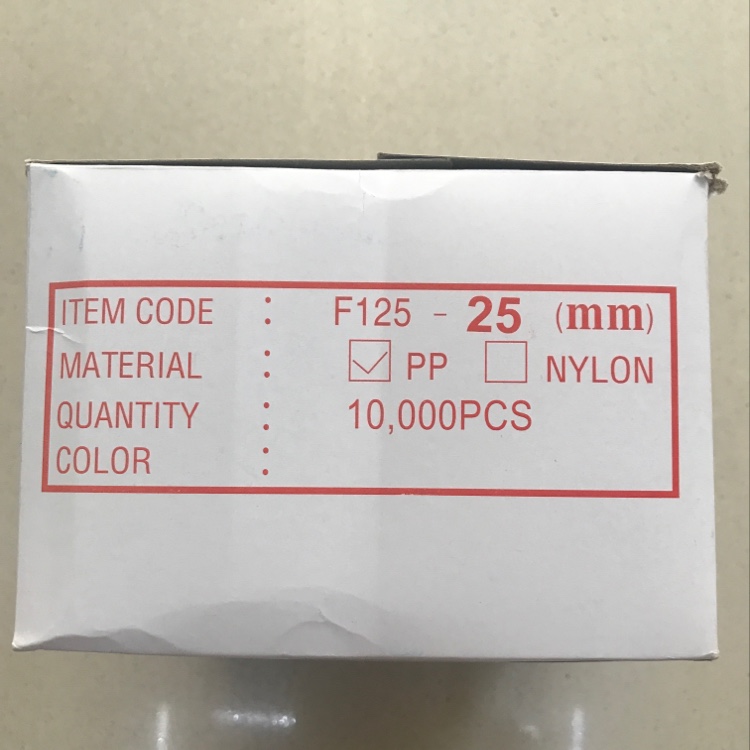

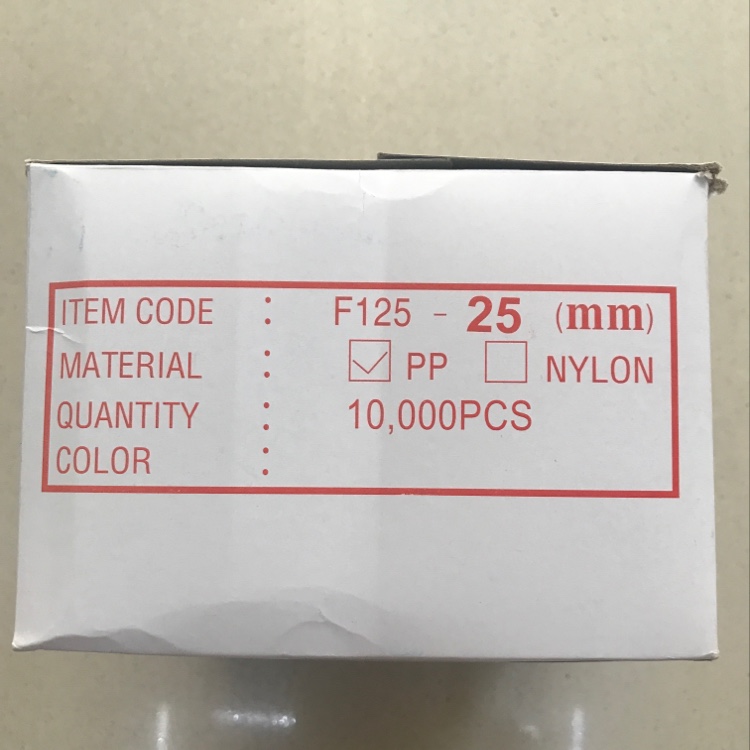

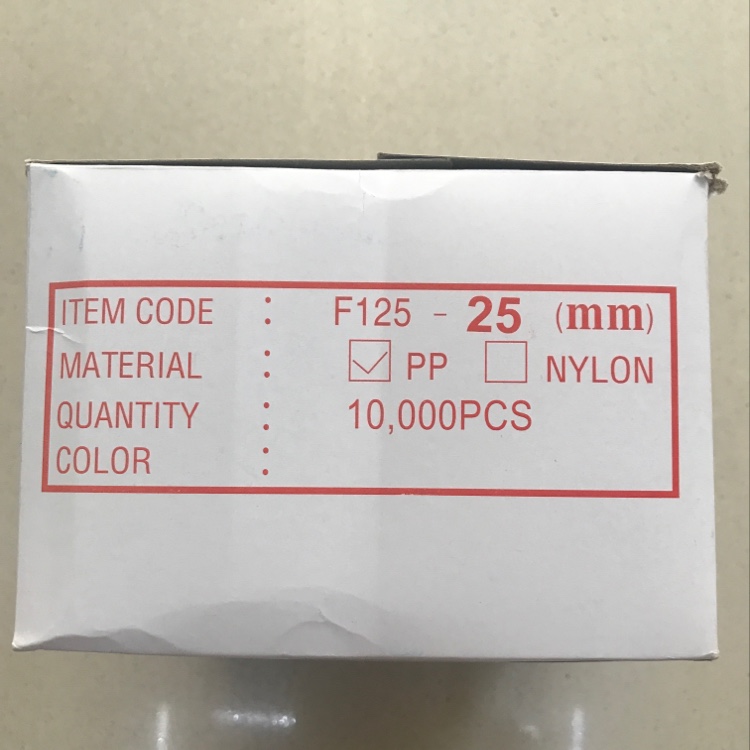

25mm Fine Gun Glue Needle Hanging Grain Tags – Durable & Precision-Crafted Labeling Solutions

Precision-engineered 25mm fine gun glue needle hanging grain tags – built for performance and reliability.

When Details Define Success: Redefining the Power of a Label

In environments where speed meets precision—be it a bustling craft studio or a fast-moving agricultural packing line—a single misplaced label can ripple into delays, errors, and customer dissatisfaction. The journey from chaos to order often begins with something as small as a tag. But not just any tag: one that combines exact dimensions with superior craftsmanship. Enter the 25mm fine gun glue needle hanging grain tag—an unassuming yet transformative tool in modern labeling systems.

The 25mm size isn’t arbitrary. It strikes the perfect balance between visibility and subtlety, offering enough surface area for essential information without overwhelming the product. Whether tagging a delicate handmade soap or a sack of organic rice, this dimension ensures clarity while preserving aesthetic integrity. When every millimeter counts, choosing the right scale is half the battle won.

The Craft Behind the Precision: Decoding the Design Philosophy

At first glance, these tags appear simple—but their design is anything but. The needle-point structure of the glue tip enables pinpoint accuracy during application, minimizing adhesive overflow and ensuring clean, consistent placement. Unlike bulkier alternatives that risk misalignment or excess glue residue, the fine needle delivers a controlled burst of adhesion exactly where needed.

The hanging grain tag’s unique construction blends rigidity with flexibility. Engineered to withstand tension during transport yet bend slightly under pressure, they resist snapping during handling. This duality makes them ideal for dynamic environments where labels endure movement, stacking, and variable climates.

Material science plays a pivotal role too. Each tag undergoes surface treatment to resist moisture, UV exposure, and abrasion. Ink adheres firmly, maintaining legibility even after weeks under warehouse lights or outdoor storage. Tear-resistant polystyrene forms the core, ensuring longevity without adding unnecessary weight.

Micro-engineered needle tip ensures precise glue delivery; reinforced loop supports secure hanging.

More Than Just a Label: Real-World Impact Across Industries

In a handcrafted candle workshop, time spent re-labeling smudged or fallen tags eats into productivity. With 25mm fine gun glue needle tags, artisans report faster turnaround, cleaner finishes, and fewer errors—all contributing to higher customer satisfaction. The ease of use allows non-specialists to apply labels confidently, reducing training overhead.

On agricultural sorting lines, where humidity and dust challenge conventional labels, these tags prove resilient. Farmers using them for seed batches or harvested produce note improved traceability and reduced waste due to illegible or detached markers. In one case study, a cooperative reduced labeling-related rejections by over 40% within two months of switching systems.

Retail warehouses face another challenge: constant handling. Standard stickers often peel off boxes after repeated scanning and shifting. These hanging grain tags, however, stay securely attached thanks to optimized glue formulation and mechanical anchoring through the needle insertion. Their visibility from multiple angles also speeds up inventory checks, cutting down cycle count times significantly.

Manufacturing Advantage: Why Direct Sourcing Delivers Greater Value

Bypassing traditional distribution chains allows us to deliver these tags straight from advanced molding facilities, where precision dies ensure uniformity across millions of units. Every batch emerges from tightly controlled processes designed for repeatability and minimal variance.

Quality control isn't an afterthought—it's embedded at every stage. From raw material inspection to post-production stress testing, each lot undergoes rigorous evaluation for tensile strength, adhesion consistency, and environmental resistance. This commitment translates into dependable performance you can trust, batch after batch.

Sustainability isn't overlooked either. Our supply chain prioritizes lean logistics and stable sourcing partnerships, enabling reliable stock availability without overproduction. This resilience means businesses can plan with confidence, knowing their labeling needs are covered long-term.

The Subtle Touches That Make All the Difference

It’s often the unseen details that elevate functionality. A slight bevel along the tag’s edges prevents scratching delicate packaging surfaces—and protects handlers from accidental nicks. Meanwhile, extensive compatibility tests confirm strong adhesion across cardboard, plastic, fabric, and even slightly textured materials, broadening application scope.

Color contrast has been carefully calibrated for optimal readability. High-luminance backgrounds paired with deep-pigment printing allow quick identification from several feet away—critical in high-volume settings where workers scan hundreds of items per shift.

The Future of Labeling Starts with the Right Foundation

As smart technologies like RFID and QR codes gain traction, physical labels remain the backbone of identification systems. They serve as fallbacks, supplements, and primary identifiers in systems not yet digitized. The 25mm fine gun glue needle tag is engineered with automation in mind—its standardized size and shape align perfectly with semi-automated applicators, preparing operations for future scalability.

Modular by design, these tags integrate seamlessly into larger inventory or branding ecosystems. Whether part of a color-coded categorization system or serving as branded touchpoints, they offer both utility and opportunity.

From One Tag to a Revolution in Efficiency

Users consistently highlight how such a small component generates outsized impact. “It changed how we manage our entire workshop,” shared a boutique soap maker from Oregon. Others praise the reduction in labeling errors and the professional impression left on clients.

Customization options open further doors: choose from various base colors, add logo printing, or adjust punch-hole positioning to fit your workflow. These aren’t just tags—they’re adaptable tools for smarter business systems.

Every time you attach one, you're not just labeling a product. You're affirming attention to detail, operational excellence, and brand credibility. In a world racing toward automation, sometimes the most powerful upgrades come in the smallest packages.